As I graduated from NW-REI I entered a job market fairly rich in offerings. Considering my unique family situation none of the options seemed right for me. All of the wind farms I looked at were far from my home in Olympia, WA. They all looked like I would either end up travelling-coming back in 6 week intervuls, or I would take a permanent job far from home paying for a second residence in a state I didn't want to live... struggling to see my family at all. What happened next seemed like a miracle. On a routine trip to the Olympia auto mall to show off our new baby and get an oil change I talked to my former boss at Titus-Will. He needed a person in the Stadium Service and Tire store. This store rests in the heart of the historical Stadium District of Tacoma, WA. It is just blocks from downtown. The opportunity here is awesome. It pays a living wage, is within reasonable commute to our home and puts me home weeknights with my sweetheart and our wonderful children.

I am expecting that the wind farm Iid like to work at will be built within @ a year near Olympia. When that time comes I anticipate being ready to transition to my new career as an O&M technician. Until then, I'm happy and healthy in Tacoma.

Starting with my education at Northwest Renewable Energy Institute, and into my career,I will be posting things of interest to me.

Monday, October 18, 2010

Friday, September 17, 2010

Siemens Smart grid

This is an interesting page. If you click on the smart grid links on this site there is a great visual representation of how the grid could all fit together. I watched a video here that was very informative. There has been much talk about smart grid, and it appears to be a very complex, expensive operation to make it.

Smart grid technology also seems to be needed to truly bring renewables online in a meaningful way.

This is one of the greatest challenges of this generation and the next.

Smart grid technology also seems to be needed to truly bring renewables online in a meaningful way.

This is one of the greatest challenges of this generation and the next.

Friday, September 3, 2010

Investing in Wind Power Is Smart — But Not How We’re Doing It

This article outlines some of the issues surrounding our current grid and transmission infrastructure. Legislators need to take heed to these issues and make changes to acomodate our changing energy economy.

Investing in Wind Power Is Smart — But Not How We’re Doing It

The answer is blowing in the wind.

Investing in Wind Power Is Smart — But Not How We’re Doing It

The answer is blowing in the wind.

Friday, August 27, 2010

Invenergy gas plant near Satsop, WA

This looks like a good use of a facility that has been just sitting for years. It was originally a nuclear plant that never was fully commissioned. Finding a use for it is great, and I feel good about gas plants in general versus some of the dirtier forms of carbon energy production. Gas is cleaner by a degree, and also is a better match for renewables. Gas can be more responsively throttled up and down to match the more fickle forms of clear energy (BPA and other power admin authorities are currently pulling their hair out trying to match the need and supply). As we build more wind farms, and look at other forms of carbon free energy, nuclear and gas will be a great combination. Our energy portfolio is definitely moving in the right direction.

Monday, August 23, 2010

Windy Flats Wind Farm

Here are a few of the pictures I took at Windy Flats, a wind farm owned by Cannon Power group, having Siemens wind turbines.

These units are fairly new, a little less than a year old. The crew at Windy Flats was welcoming, and informative. We were able to climb to the first landing. Not very far, but it was exciting. That was my first ladder time. I'm jazzed to get to the top. Hello! Climb test!

The landscape around this wind farm is impressive. Conditions can be harsh. They have cold winters, and hot summers. I was very impressed with both Cannon Power, and Siemens. One of the reasons that I am excited to work in wind, is the positive attitudes of the employers and employees that I have come in contact with.

Saturday, August 21, 2010

Graduation!!

The time has come! Graduation August 18th was an exciting turning point. I'm looking for work, excited to enter the Wind Industry.

NW-REI taught me a lot about myself, and teamwork. I learned from my instructors, and also from my fellow students. I am looking out at the renewable energy sector charged with enthusiasm for making a positive change.

The answer is blowing in the wind.

NW-REI taught me a lot about myself, and teamwork. I learned from my instructors, and also from my fellow students. I am looking out at the renewable energy sector charged with enthusiasm for making a positive change.

The answer is blowing in the wind.

Friday, July 23, 2010

Wednesday, July 14, 2010

PLC / Job Placement

Program logic controller module has been fun. Our instructer is very knowlegable, and the subject matter is important and interesting. PLC's are everywhere in industry. They control machine outputs based on inputs using machine logic. Programming them is an interesting task. Likely I will not be required to program as a Technician, however knowing what goes into the PLC logic allows a technician to troubleshoot system faults. Troubleshooting has taken up a large amount of time in class. This is a subject that I am sure will be reinforced by work in the field.

This week is also mock-interview week. One of our job placement staff recorded interviews of us in groups, and gave us valuable feedback on our performance.

Next week we are eligable to apply for jobs. I am excited to start that process. The time I have been waiting for has come where the jobs I see in the field may be the jobs I will be applying for. Before this time my jobsearch has been more tuned to gaining general insight into the job market. I am so thrilled to be entering the renewable energy sector at a critical time of change in our modern erergy system. Public awareness, government incentives, and technology have met in a trifecta of change. The catastrophy in the Gulf region stand as a catalyst for change, and people worldwide have become more and more aware of the need to revolutionize how we think about, consume, and produce power.

This week is also mock-interview week. One of our job placement staff recorded interviews of us in groups, and gave us valuable feedback on our performance.

Next week we are eligable to apply for jobs. I am excited to start that process. The time I have been waiting for has come where the jobs I see in the field may be the jobs I will be applying for. Before this time my jobsearch has been more tuned to gaining general insight into the job market. I am so thrilled to be entering the renewable energy sector at a critical time of change in our modern erergy system. Public awareness, government incentives, and technology have met in a trifecta of change. The catastrophy in the Gulf region stand as a catalyst for change, and people worldwide have become more and more aware of the need to revolutionize how we think about, consume, and produce power.

Tuesday, June 29, 2010

PLC's

http://en.wikipedia.org/wiki/Programmable_logic_controller

These devices are very interesting. I have a lot to learn. We started in class last night reviewing the basic logic concepts we started to explore in electrical. Using ladder diagrams, and machine logic, PLC's are programmable, and can be wired to inputs and outputs eliminating complex wiring or relay conglomerations. They are a clean, flexible format that can be changed quickly and easily. There are PLC's in many systems we use regularly. In this course we will be taught enough to do diagnostics on systems that use PLC's and be able to identify the parts of a PLC's inner workings. We will use this knowlege to identify problems and troubleshoot for solutions.

PLC's are used in industry to moniter and regulate the function of Wind Turbines. I am looking forward to this month's coursework.

Also this month I will be beginning job search. My resume and cover letters are shaping up, and I am getting excited to start finding work.

These devices are very interesting. I have a lot to learn. We started in class last night reviewing the basic logic concepts we started to explore in electrical. Using ladder diagrams, and machine logic, PLC's are programmable, and can be wired to inputs and outputs eliminating complex wiring or relay conglomerations. They are a clean, flexible format that can be changed quickly and easily. There are PLC's in many systems we use regularly. In this course we will be taught enough to do diagnostics on systems that use PLC's and be able to identify the parts of a PLC's inner workings. We will use this knowlege to identify problems and troubleshoot for solutions.

PLC's are used in industry to moniter and regulate the function of Wind Turbines. I am looking forward to this month's coursework.

Also this month I will be beginning job search. My resume and cover letters are shaping up, and I am getting excited to start finding work.

Hydraulics

This module taught me a lot about working with hydraulics. The information in the section was very rich. I studied schematics, and learned about Pascal and fluid pressure. I discovered many devices I had no idea existed before taking this class. The quizzes were challenging yet rewarding. The final was very difficult. I am relieved to have completed that coursework, and am looking forward to the PLC section of this diploma program.

Saturday, June 5, 2010

Hydraulics

The first week of my hydraulics course (4th month) in this wind turbine tech program has been very informative and exciting. Our instructor has real turbine experience. He worked for Vestas, and his sharing of knowlege and ability to teach has been very fun.

There is a written curriculum in which we are learning the principals of hydraulic devices, and interpreting and drawing schematic diagrams. We use training tables that have a selection of DCV's, needle valves, flow meters and guages. There is a range of lengths of hydraulic hose with Quick connect fittings, and we use pictoral or schematic diagrams to reproduce many fluid power configurations on the trainers.

I never guessed before this class how engaging hydraulics could be. I am very excited about the education I am getting in this class, and in this program as a whole.

There is a written curriculum in which we are learning the principals of hydraulic devices, and interpreting and drawing schematic diagrams. We use training tables that have a selection of DCV's, needle valves, flow meters and guages. There is a range of lengths of hydraulic hose with Quick connect fittings, and we use pictoral or schematic diagrams to reproduce many fluid power configurations on the trainers.

I never guessed before this class how engaging hydraulics could be. I am very excited about the education I am getting in this class, and in this program as a whole.

Friday, June 4, 2010

Wild Horse Wind park

Wild Horse

There are 149 Vestas turbines used at the PSE wind farm in Kittitas.

These photos were taken from the winding road that takes visitors to the tour center near the top of the farm.

What impressed me the most is the sound/feeling of the air moving around the blades. With a blade tip speed of 150MPH, the turbulence under/near these machines is impressive.

The visitor center is very nice. There were PSE personnel on site that were very informative and welcoming.

The center has on display some very nice models, and examples of the technologies being used at the facility.

I personally liked the touch of a older generation wind mill at the entrance.

To the rear of the visitor center is a small bank of solar cells that produces plenty of power most days to run the visitor center. This renewable aproach to the center was a big plus, and impressed me. It shows their commitment to renewables.

After a very informative presentation in the conference room of the visitors center, we put on hard hats, and safety glasses, and drove up to the top of the wind park. Safety guidelines provided by the state mandated that the wind farm go no farther than 4000 ft, and the top of Whiskey Dick Mountain sits at 3900 ft of elevation. This made installing turbines at the top of the facility impossible, so PSE turned to solar. They installed a 3500 cell array that provides .5 MW of power. The solar array compliments the ups and downs of the wind. On windy days, the skies are gray for the most part, but when the turbines die down, and the air is still, solar seems to be a strong player in the energy dynamic at Wild Horse.

Next we drove down the hill to a turbine that we were able to go inside of. We looked at the PLC, the ladder that heads up the tower sections to the nacelle, and talked about the construction of the wind machine.

This close up view of a wind turbine left me feeling excited for my first climb. I am feeling more and more passionate about wind energy, and proud to have made a leap of faith in a direction I can believe in.

I feel fortunate, as well as proud to have become involved with renewable energy and look forward to a time in the near future when I can contribute directly to the unfording of the next generation of electricity production. A bright, clean new era.

On my trip to PSE's Wild Horse Wind farm I stopped by this Invenergy site to see turbines pre-commission.

These GE's are going in at Kittitas, WA and they were a fun bonus to my trip.

When I first saw these I thought they were part of the Wild Horse project, and it was after it registered that none of them were moving that I realized they were a whole seperate farm.

Saturday, May 29, 2010

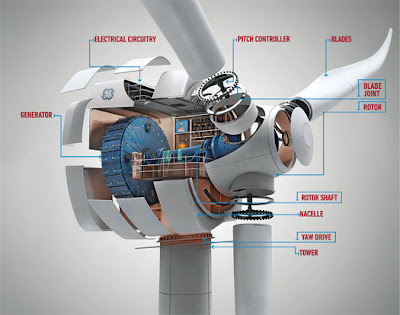

GE has broken new ground in their newest turbine design. This gearless generator has so much potential. It is almost certain to revolutionize turbine repair and maintainance. This turbine is also a 4mw generator making it a hard hitter in the realm of energy generation. The electricity produced with one, the less footprint made on ocean floors. The footprint issue is also a concern for land based installations where the number of acres covered by footings and foundations cuts in (however minimally) to agricultural use and vegetation habitit.

Some technicians could get sucked into the old-world way of thinking "less job security-less maintainance",

but considering the number of technicians that will be needed to meet the renewable energy mandates of the coming 20 years, I am not concerned. This design class will make renewable energy cost less, and therefore will make it even more preferable to non-renewables.

Credit for this image goes to POPSCI and GE. I lifted it from this nice article http://www.popsci.com/technology/article/2010-03/next-gen-wind-turbine

and hope that my using it will benefit GE and the wind industry.

Possibly the largest benefit to lower maintainance designs is that they become more usable in off-shore and hard to reach applications where they will be out of the way, and capitalize on harsher conditions where there is more wind to be harnessed.

These ocean and lake based installs (see Lake Erie)

offer much potential, but are very difficult and costly to service and maintain.

This recent innovation in low-maintainance turbines stands to push off-shore applications to the forefront. They effect wildlife less, and counter the weak but prevalent "eyesore" complaint from wind energy opponents.

Saturday, May 15, 2010

There is a Vestas V15 at my school now to look at and work on. We are enjoying opportunities to discuss how it works, and look at a real-life example. On this trip to see it we were discussing how to possibly build an adjustable bracket for the Generator to sit on so that its alignment could be checked and adjusted easily.

This is the hub and the forward shaft. This assembly is sometimes simply called the Rotor.

The gearbox (yellow part) increases the rotor's initial slow shaft speed to 1800 RPM's required by the generator to make A/C power.

This is the high-speed shaft and generator. The second smaller generator is used at off-peak times when the rotor speed is not enough to operate the main generator.

Monday, May 10, 2010

Mechanical

In the 3rd module of NW-REI's curriculum I am learning about many things mechanical. We have studied gear drives, shafts, fasteners (keys), and are moving into bearings and multiple shaft drives.

This has been a very informative section so far, with more lab work than written material. The trainers we use have a bed-plate with various mounting configurations drilled into it, a few motor types, and a large selection of mounting spacers, gears, hardware, shafts, and a tool selection. We have experimented with various gear set-ups and what written material there is coincides sensibly to the physical practice we are getting in class. So much of this makes perfect sense for turbines. I can see that the functions we are performing relate directly to the mechanical repairs we will be performing on wind machines.

I like this picture. It is an automotive image however many of the gear types are gears that reside in gearboxes inside the turbine nacelles that increase main rotor shaft speeds from 12-20 up to 1800 rpm's.

Some of these machines weigh as much as 18 tons.

The answer is blowing in the wind.

This has been a very informative section so far, with more lab work than written material. The trainers we use have a bed-plate with various mounting configurations drilled into it, a few motor types, and a large selection of mounting spacers, gears, hardware, shafts, and a tool selection. We have experimented with various gear set-ups and what written material there is coincides sensibly to the physical practice we are getting in class. So much of this makes perfect sense for turbines. I can see that the functions we are performing relate directly to the mechanical repairs we will be performing on wind machines.

I like this picture. It is an automotive image however many of the gear types are gears that reside in gearboxes inside the turbine nacelles that increase main rotor shaft speeds from 12-20 up to 1800 rpm's.

Some of these machines weigh as much as 18 tons.

The answer is blowing in the wind.

Sunday, April 18, 2010

Circuits

Module 2:Electrical

We have learned the basics of Fluke meter operation, electrical safety, and Ohms law. We have been working on series, parallel, and combination circuits. We have built basic circuits on trainers and tested them.

This week we began learning about inductors and capacitors. This upc oming week we will be delving into transformers.

We have learned the basics of Fluke meter operation, electrical safety, and Ohms law. We have been working on series, parallel, and combination circuits. We have built basic circuits on trainers and tested them.

This week we began learning about inductors and capacitors. This upc oming week we will be delving into transformers.

Thursday, April 8, 2010

Ohm's Law

Module 2:Electrical

Ohm's Law, calculating Voltage, Amperage, and Resistance...The teacher is great, the content is important.

I plan on studying hard and testing well. All this content will truly apply in my actual work environment.

Ohm's Law, calculating Voltage, Amperage, and Resistance...The teacher is great, the content is important.

I plan on studying hard and testing well. All this content will truly apply in my actual work environment.

Saturday, April 3, 2010

Poor, poor Birdies!

One of the only downsides that anyone can state about the viability of wind power, is that they can be destructive to birds and bats. Shocking as it is that some environmental activists would oppose such a healthy energy production method, organizations such as the audobon society have worked surprisingly hard to oppose them.

Here is an interesting fact sheet comparing wind turbine deaths with other forms of human caused bird fatalities. http://www.currykerlinger.com/birds.htm

Before anyone cries for the poor birdies that run into propellers on the cleanest power generators in the world, they better be out rallying for the removal of all glass from buildings. And getting off their cel-phones.. and living without electricity..that's your computers too. and not using any automated transportation. The bird fatality by turbine numbers are dwarfed by all other sources of deaths.

The answer is blowing in the wind.

Here is an interesting fact sheet comparing wind turbine deaths with other forms of human caused bird fatalities. http://www.currykerlinger.com/birds.htm

Before anyone cries for the poor birdies that run into propellers on the cleanest power generators in the world, they better be out rallying for the removal of all glass from buildings. And getting off their cel-phones.. and living without electricity..that's your computers too. and not using any automated transportation. The bird fatality by turbine numbers are dwarfed by all other sources of deaths.

The answer is blowing in the wind.

Wednesday, March 31, 2010

14th century wind power

I find it interesting that in the 14th century, people were already daydreaming about being wind techs.

There is something magical about capturing the wind's energy.

Tuesday, March 30, 2010

White Creek Wind Project, Goldendale, WA

White Creek wind project

9,500 acres

21 miles from Goldendale, WA

The nation’s largest wind project owned by public power providers

Construction began July 2006

Parts were delivered September 2007

89 units completed by October and producing power by November 07

Total project cost was about $360 million

http://www.res-americas.com/ RES America was the construction contractor

• Improvements to 11 miles of county and state highways

• 33 miles of fiber optic and electrical cable, 14 miles of transmission line

• 2 substations with 1800MW total capacity

• contracted forecasting duties to ( http://www.3tier.com/en/ ) providing accurate wind forecasting

• White Creek Wind is also reviewing plans to expand output by an additional 100 Megawatts,

using another 40-50 wind turbines

205 MW project will use 89 Siemens 2.3 MW wind turbines, producing enough power for 38,000 residences

9,500 acres

21 miles from Goldendale, WA

The nation’s largest wind project owned by public power providers

Construction began July 2006

Parts were delivered September 2007

89 units completed by October and producing power by November 07

Total project cost was about $360 million

http://www.res-americas.com/ RES America was the construction contractor

• Improvements to 11 miles of county and state highways

• 33 miles of fiber optic and electrical cable, 14 miles of transmission line

• 2 substations with 1800MW total capacity

• contracted forecasting duties to ( http://www.3tier.com/en/ ) providing accurate wind forecasting

• White Creek Wind is also reviewing plans to expand output by an additional 100 Megawatts,

using another 40-50 wind turbines

205 MW project will use 89 Siemens 2.3 MW wind turbines, producing enough power for 38,000 residences

Wind turbine self rescue

This all looks very fun and exciting to me.

Nice video of a pricarious self-rescue. I'll be doing this about 6 months from now.

Saturday, March 27, 2010

MAGLEV turbine

Maglev is a company interested in making a huge turbine that is a VAWT(vertical axis wind turbine). It uses a series of permanent magnets causing the upper rotor assembly to levitate above the base reducing friction. This could lengthen service life of the turbine, and because of the size, less turbines would be needed to make the same power.

Thursday, March 25, 2010

Intro to Wind

This last week has required lots of studying. We have been learning about Rigging, preparing a load for lifting/hoisting. We are studying cranes, hoists, slings etc.

It is a very in-depth study, with plenty of applied math. We have been calculating load angle loss, crush force, mechanical advantage, and lift-force ratios.

There is not much to tell here, without teaching the material. It is important to know for my work in the field.

Tomorrow we are doing our rigging final, and Monday is our Rigging Practical test.

Some of next week should be a little slack with some prep-work for my next segmant which is electrical.

The education breakdown is in 6 one month segments;

Intro to Wind

Electrical

Mechanical

Hydraulics

Program Logic Controllers

Metallurgy

The more I learn about this occupation, the more hopeful I get.

I am open to maintainance, and interested in being a technician, as well as construction. All branches seem to be exciting.

From my time in High Adventure (scouting), I have some rock-climbing experience. Turbine Technician work looks a lot like that. Wearing a body harness, a technician is working with ropes and lanyards, minding fall protection and safety equipment at all time.

It is a very in-depth study, with plenty of applied math. We have been calculating load angle loss, crush force, mechanical advantage, and lift-force ratios.

There is not much to tell here, without teaching the material. It is important to know for my work in the field.

Tomorrow we are doing our rigging final, and Monday is our Rigging Practical test.

Some of next week should be a little slack with some prep-work for my next segmant which is electrical.

The education breakdown is in 6 one month segments;

Intro to Wind

Electrical

Mechanical

Hydraulics

Program Logic Controllers

Metallurgy

The more I learn about this occupation, the more hopeful I get.

I am open to maintainance, and interested in being a technician, as well as construction. All branches seem to be exciting.

From my time in High Adventure (scouting), I have some rock-climbing experience. Turbine Technician work looks a lot like that. Wearing a body harness, a technician is working with ropes and lanyards, minding fall protection and safety equipment at all time.

Friday, March 19, 2010

For those interested in learning a little more about Wind Energy around the world, a nice clean Wiki listing is here: http://en.wikipedia.org/wiki/Wind_power.

There is a lot of information to take in out on the web, and knowing even a little bit of it can help further the cause of big wind. Wind Energy provides a form of electricity that is close to the most efficient and inexpensive forms of power. Even more importantly, as we head into more and more complicatedpolitics and ecological issues around energy, Wind is ever more the premier choice for satisfying our hunger for juice.

Wind energy produces no carbon emissions. When operating, a wind turbine consumes no water, no fuel, and no air. Nothing is burnt or consumed in the making of wind energy.

There are no measurable levels of polutants emitted by wind turbines during operation, and most maintain an uptime of 95-98%. This means that even considering maintainance, almost every turbine installed is ready to make power at all times.

1-2 year studies are conducted on future wind park sites using MET towers (meterological equipment) to determine the usefulness of a site for wind energy. To me this means simply that turbines are almost all always on and generating. As technology comes along with improvements, and more service technicians are available and competently trained, turbine efficience will improve, and service life will be lengthened.

There is a lot of information to take in out on the web, and knowing even a little bit of it can help further the cause of big wind. Wind Energy provides a form of electricity that is close to the most efficient and inexpensive forms of power. Even more importantly, as we head into more and more complicatedpolitics and ecological issues around energy, Wind is ever more the premier choice for satisfying our hunger for juice.

Wind energy produces no carbon emissions. When operating, a wind turbine consumes no water, no fuel, and no air. Nothing is burnt or consumed in the making of wind energy.

There are no measurable levels of polutants emitted by wind turbines during operation, and most maintain an uptime of 95-98%. This means that even considering maintainance, almost every turbine installed is ready to make power at all times.

1-2 year studies are conducted on future wind park sites using MET towers (meterological equipment) to determine the usefulness of a site for wind energy. To me this means simply that turbines are almost all always on and generating. As technology comes along with improvements, and more service technicians are available and competently trained, turbine efficience will improve, and service life will be lengthened.

Wednesday, March 17, 2010

LIDAR

LIDAR http://en.wikipedia.org/wiki/LIDAR

is a new technology that, when used in wind turbines allows the rotating ability of an upwind turbine (for keeping it pointed into the wind) can sense not only where the wind has been via a wind vein, but can also sense where the wind will be. This new advancement will bring longevity and efficiency to wind production. It will reduce wear on internal components and rotors by maintaining optimal yaw (rotation) as well as optimized yaw angle.

is a new technology that, when used in wind turbines allows the rotating ability of an upwind turbine (for keeping it pointed into the wind) can sense not only where the wind has been via a wind vein, but can also sense where the wind will be. This new advancement will bring longevity and efficiency to wind production. It will reduce wear on internal components and rotors by maintaining optimal yaw (rotation) as well as optimized yaw angle.

This is a nice simplified drawing of a Horizontal Axis Wind Turbine that is using upwind construction. The rotor assembly is ahead of the turbine in the wind stream. One complication of this design, is that a yaw drive, or tail is required to keep these unstable designs pointed into the wind. This unit has a yaw drive (numbers 13/14) they take info from the wind vein which turns motors and actuators. The large gear is affixed to the tower, and the smaller gears are firmly mounted on the nacelle. Many of the most commonly installed units today are upwind, steel tube constructed.

My journey starts here:

I am from Olympia, WA. I found nw-rei on the internet after being tipped off about the wind industry. I just started to google around. The biggest reason I initially checked into it is its proximity to my home. When I requested more info from the school on their automatic contact email, Julie Reppen called me the very next day on my cel, and was a very proactive recruiter.

From that day, I think it was no more than 2 weeks that I was accepted into the program. My life has been a whirlwind ever since.

I started my first week at NW-REI March 8th. There is not much to tell about the first week... orientation, student handbook, Math placement test, Physical test.

This week starting March 15th has had a lot more substance. We started the "Intro to Wind Tech" portion of the month. There have been several hours of fascinating slides and periods of class discussion. We had a visit yesterday from Mike Merrick. He has many years of dedicated work in the wind industry. His classroom discussion in lively, dynamic, pointed, and informative. Nothing compares to a teaching style developed from raw experience.

Today my class has a quiz on the last two days of information. We will get more information tonight and tomorrow, and quiz again on Friday.

I'll try to post the two internet labs my group put together. The photos are probably copyrighted, and I apologize for snipping them for this purpose.

From that day, I think it was no more than 2 weeks that I was accepted into the program. My life has been a whirlwind ever since.

I started my first week at NW-REI March 8th. There is not much to tell about the first week... orientation, student handbook, Math placement test, Physical test.

This week starting March 15th has had a lot more substance. We started the "Intro to Wind Tech" portion of the month. There have been several hours of fascinating slides and periods of class discussion. We had a visit yesterday from Mike Merrick. He has many years of dedicated work in the wind industry. His classroom discussion in lively, dynamic, pointed, and informative. Nothing compares to a teaching style developed from raw experience.

Today my class has a quiz on the last two days of information. We will get more information tonight and tomorrow, and quiz again on Friday.

I'll try to post the two internet labs my group put together. The photos are probably copyrighted, and I apologize for snipping them for this purpose.

Subscribe to:

Comments (Atom)